As case counts shot up, classes shut down and NJIT students scrambled to get home safely in March 2020, the engineers at the NJIT Makerspace began to plan.

“In mid-March, when it was pretty clear that this was going to be a huge challenge to the healthcare system, we asked ourselves what we could do,” said NCE Dean Moshe Kam in an interview with the NJIT Alumni Association. “When we closed NJIT and moved it all to remote access, we decided that we would keep the Makerspace open.”

The Makerspace is a collaborative prototyping and manufacturing facility, one of the largest of its kind on the East Coast. Students looking to turn their ideas into reality can find everything from 10-foot waterjet cutters to high-quality Ultimaker 3D-printers. In the midst of a PPE shortage, with doctors and nurses wearing week-old masks or even garbage bags for protection, the Makerspace was well-equipped to respond to the crisis.

“Engineers, of course, are very innovative individuals. Immediately we had more than 100 suggestions on what to do…In consultation with hospitals around here, especially St. Michael’s, we decided that we would manufacture high quality face shields,” said Kam. “We decided not to do 70 different things. We decided to do one thing and do it well.”

The Makerspace team tasked to design this face shield had several problems to solve and features to balance. What existing facilities were ready to be utilized? Should the shield be disposable or reusable? How could they strike a balance between construction speed and durability? How could they keep the unit cost down?

Each design had its tradeoffs and advantages. For example, 3D-printed shields are simple and cheap, but time-consuming and ultimately unsafe – the porous plastic is susceptible to collecting bacteria after repeated use. Ultimately, after considering sustainability, safety and their available resources, the Makerspace engineers sought to design a shield that was durable and reusable.

Daniel Sosa, the Makerspace Fabrication and Manufacturing specialist, began the design process with sketches. Within a week of originally being given the task of designing a reusable shield, the team jumped into action, using Makerspace machinery like the laser cutter to quickly build the first prototype.

To begin production on a larger scale, the team recruited volunteers from the NJIT community. Here, they encountered the first of many challenges with speed and efficiency. “We set up an assembly line…but each person would go through the process and do one step. One person is putting on the strap through. One person is putting the shield on. One person puts the foam on…and so on and so forth,” said Justin T. Suriano, the Makerspace Manager.

The first solution they pursued was to buy more machinery. Dan Brateris, Director of Experiential Learning at NJIT, spearheaded the effort to procure additional tools that could accelerate the process. At the suggestion of Dr. Sam Lieber, an assistant professor in NJIT’s applied engineering school, the Makerspace purchased a drag knife machine to optimize production. “We got a very large rod to hold the spools. So, we were holding, I wanna say three 500-pound spools on this rod and pulling them onto the drag knife, and we had a program that was able to cut something like 72 shields at a time” Suriano said.

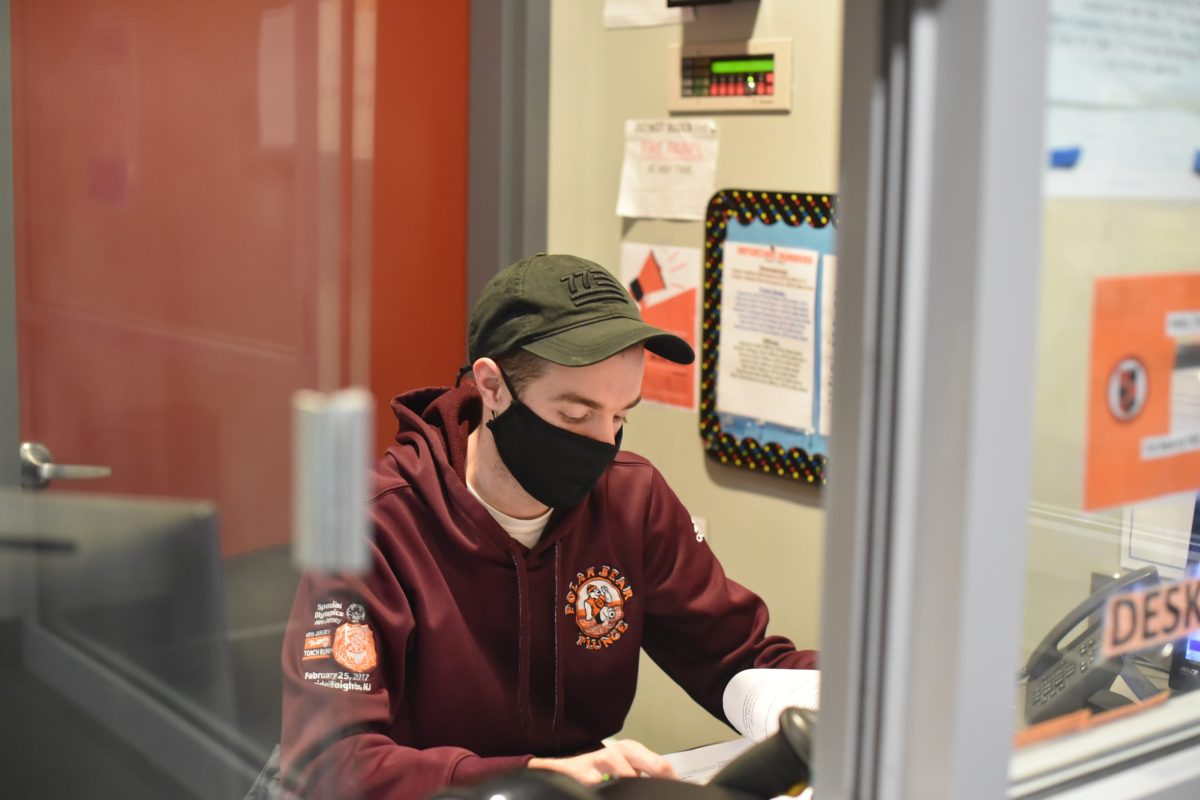

Another path explored was designing new tools in-house. Ryan Helly, a student worker at the Makerspace invented a mechanism to automate the task of punching the tabs in the band into the PET.

“It wasn’t like we just ordered all of these parts and some manufacturer just sent them to us. We ordered the raw materials, we took them in and we created systems and processes to actually turn these raw materials into something that we could use,” said Joseph Oliveira, one of the student workers who led the face shield project alongside Adam Steinmark.

The face shield assembly operations scaled up most significantly with the Makerspace’s partnership with the CommonHealth Project, a community initiative started by NJIT students to home-delivers shield construction kits to volunteers and donate PPE to healthcare centers that need it most. With its decentralized network of delivery drivers and constructors, the model of the CommonHealth Project presented a scalable alternative to assembly-line operations. Packaging the Makerspace’s materials into construction kits for the CommonHealth Project to deliver allowed them to take over the shield assembly operations, while the Makerspace could focus on manufacturing the parts themselves.

“They have been able to accelerate what we have been doing. They also were able to make sure that we are connecting with hospitals, nursing homes and other medical facilities of all kinds that had difficulty getting PPE… This was very impressive on account of seeing what the Makerspace staff was able to do, because we really converted the Makerspace from an educational facility to a production facility,” said Dean Kam. “Very efficient and in high volume. And then there was this group of tireless students who arranged this assembly.”

After successfully building nearly 20,000 shields in conjunction with The CommonHealth Project, the Makerspace has taken their experience to continue innovating in other projects on NJIT’s campus. With the recent adoption of 360° Meeting Owl cameras in converged learning classrooms, Adrian Olmeda, the Prototyping and Design Specialist at the Makerspace, was able to develop a system to safely house, secure and transport the cameras across campus in carts. In addition to that project, Dan Brateris built a pedal-operated, hands-free hand sanitizer dispenser that may be implemented onto campus.

The Makerspace gives Highlanders all the tools they need to build and create anything from 3D-printed keychains to custom furniture pieces. When prompted on the Makerspace’s role on campus in the future, Suriano said, “It’s to connect all of the theory you learned in classes with the machinery, the fabrication equipment, the atmosphere that’s in the space. What I would like to see is more people in the Makerspace engaging in making, collaborating and just honestly having a good time.” The Makerspace’s summer success is a testament to its exciting creative resources that NJIT students shouldn’t miss out on.